RING JOINT GASKETS

RTJ gaskets are produced in different solid metal types. They are used for high pressure (till 1300 bar) and for high temperature (till 1000°C) and are used where corrosive agents are presents. These gaskets are obtained by mechanical working from forged or laminated metals. RTJ find their mainly application in refining process in crude extraction and in high pressure applications. For their production we use the last edition of the API standard. FMI can supply oval and octagonal ring joint, BX and RX for all applications to suite the flanges design with standard and special styles.

R Type Gasket

The R Type Joint Gasket is initially developed for high pressure/ temperature applications which found in the petroleum industry and is primarily used in the oilfield on drilling and completion equipment.

However, today this product range can also be found on valves and pipe work assemblies, along with some high integrity pressure vessel joints.

Style R gaskets are manufactured in accordance with both API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

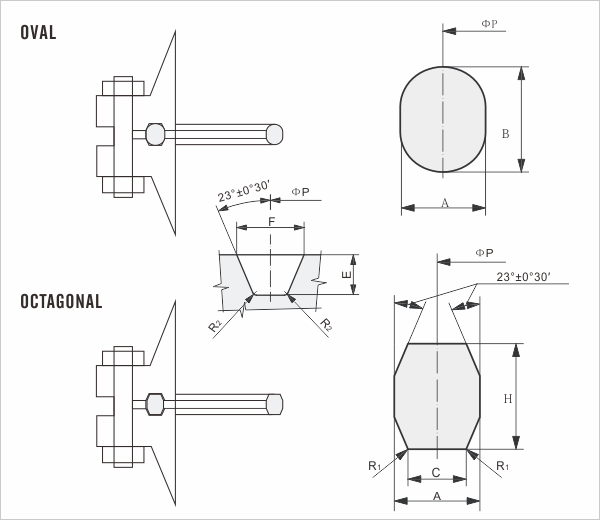

API ring Joint gaskets come in two basic types, an oval cross section and an octagonal cross section. These basic shapes are used in pressures up to 10,000 psi. The dimensions are standardized and require specially grooved flanges. The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. However, only the oval cross section can be used in the old type round bottom groove. The newer flat bottom groove design will accept either the oval or the octagonal cross section. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 micro inches and to be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or an edging action as the compressive forces are applied.

The hardness of the ring should always be less than the hardness of the flanges to prevent flange deformation. Dimensions for API ring joint gaskets and grooves are covered in ASME B16.20 and API6A

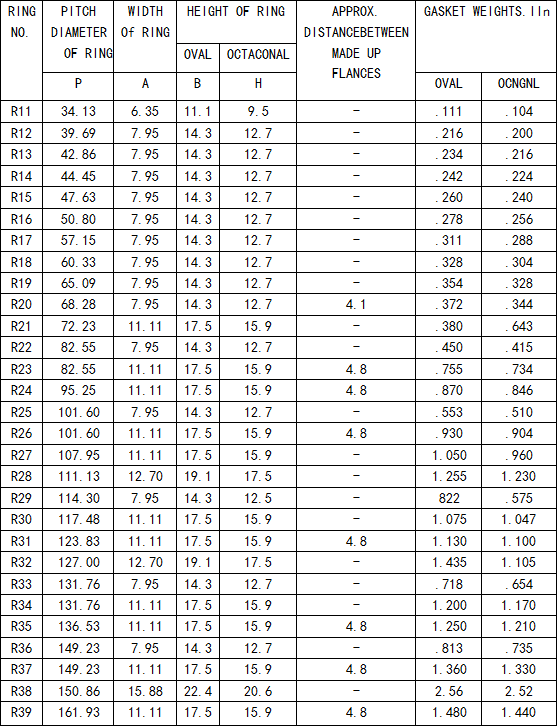

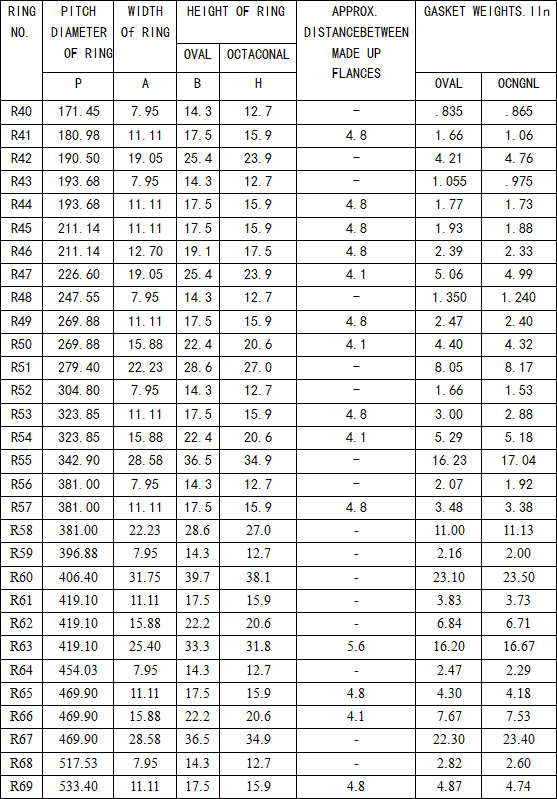

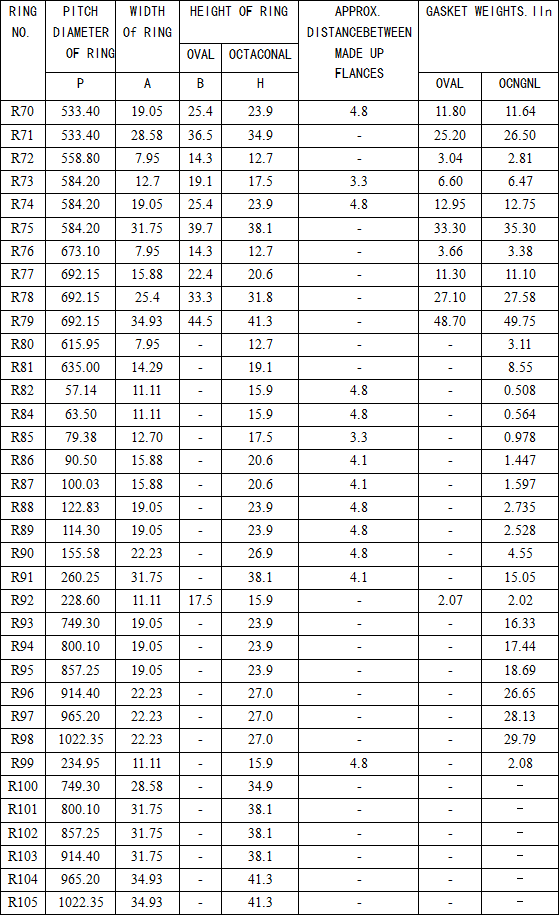

Apex stocks a wide range of sizes and materials ready for immediate shipment from R11 to R105. Pressure: 2,000-5,000 PSI

DIMENSIONAL DATA – STYLE R

TOLERANCES:(mm)

A(width of ring ) ±0.20 B,H (height of ring) ±0.5 P(average pitch diameter of ring)±0.18 23° (angle) ±1/2°

Style R Ring Type Jonints can be manufactured in accordance with all relevant standards to suit the following flange designations

API6A ASME/ANSI B16.5 MSS SP44 (ASME B16.47 SERIES A) BS 1560