RING JOINT GASKETS

RTJ gaskets are produced in different solid metal types. They are used for high pressure (till 1300 bar) and for high temperature (till 1000°C) and are used where corrosive agents are presents. These gaskets are obtained by mechanical working from forged or laminated metals. RTJ find their mainly application in refining process in crude extraction and in high pressure applications. For their production we use the last edition of the API standard. FMI can supply oval and octagonal ring joint, BX and RX for all applications to suite the flanges design with standard and special styles.

BX Type Gasket

Style BX type RTJ gaskets are manufactured in accordance with both API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges.

The BX is designed to fit the same groove design as a standard Style R, making the joints interchangeable. The modified design uses a pressureenergized effect that improves the efficiency of the seal as the internal pressure of the system increases.

Pressure: 5,000-20,000 PSI

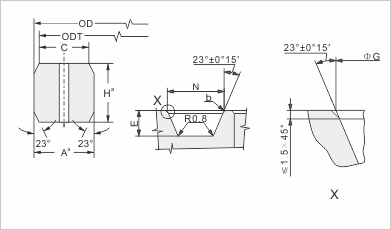

DIMENSIONAL DATA – STYLE BX

TOLERANCES:(mm)

A*(width of ring) +0.20,-0.000 A*(hole size) ±0.5 H*(height of ring) +0.20,-0.000 OD(od of ring) +0.000,-0.150 23*(angle) ±1/4°

NOTE 1: Radius of the ring shall be 8% to 12% of the ring height ‘H’.

One pressure passage hole required per ring on centre line *A plus tolerance of 0.008 inches for width *A* and height *H* is permitted. provided the variation in width or height does not exceed 0.004 inches throughout its entire circumference

| RING

NO. |

PRESSLURE ALASSES, API 6BX | OUTSIDE

DIAMETER OF RING OD |

HELCHT

OF RING H |

WIDTH

OF RING A |

HOLE

SIZE D |

GASKET

WELGHT. Ibs. for APL 66x flanges |

|||||

| 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | ||||||

| BX150 | – | – | – | 1 11/16 | 1 11/16 | – | 72.19 | 9.30 | 9.30 | 1.59 | 0.295 |

| BX151 | – | – | – | 1 13/16 | 1 13/16 | 1 13/16 | 76.40 | 9.63 | 9.63 | 1.59 | 0.337 |

| BX152 | – | – | – | 2 1/16 | 2 1/16 | 2 1/16 | 84.68 | 10.24 | 10.24 | 1.59 | 0.425 |

| BX153 | – | – | – | 2 9/16 | 2 9/16 | 2 9/16 | 100.94 | 11.38 | 11.38 | 1.59 | 0.632 |

| BX154 | – | – | – | 3 1/16 | 3 1/16 | 3 1/16 | 116.84 | 12.40 | 12.40 | 1.59* | 0.875 |

| BX155 | – | – | – | 4 1/16 | 4 1/16 | 4 1/16 | 147.96 | 14.22 | 14.22 | 1.59 | 1.22 |

| BX156 | – | – | – | 7 1/16 | 7 1/16 | 7 1/16 | 237.92 | 18.62 | 18.62 | 3.18 | 4.14 |

| BX157 | – | – | – | 9 | 9 | 9 | 294.46 | 20.98 | 20.98 | 3.18 | 6.55 |

| BX158 | – | – | – | 11 | 11 | 11 | 352.04 | 23.14 | 23.14 | 3.18 | 9.60 |

| BX159 | – | – | – | 13 5/8 | 13 5/8 | 13 5/8 | 426.72 | 25.70 | 25.70 | 3.18 | 14.41 |

| BX160 | – | – | 13 5/8 | – | – | – | 402.59 | 23.83 | 13.74 | 3.18 | 6.75 |

| BX161 | – | – | 16 3/4 | – | – | – | 491.41 | 28.07 | 16.21 | 3.18 | – |

| BX162 | – | – | 16 3/4 | 16 3/4 | 16 3/4 | – | 475.49 | 14.22 | 14.22 | 1.59 | – |

| BX163 | – | – | 18 3/4 | – | – | – | 556.16 | 30.10 | 17.37 | 3.18 | – |

| BX164 | – | – | – | 18 3/4 | 18 3/4 | – | 570.56 | 30.10 | 24.59 | 3.18 | – |

| BX165 | – | – | 21 1/4 | – | – | – | 624.71 | 32.03 | 18.49 | 3.18 | – |

| BX166 | – | – | – | 21 1/4 | – | – | 640.03 | 32.03 | 26.14 | 3.18 | – |

| BX167 | 26 3/4 | – | – | – | – | – | 759.36 | 35.87 | 13.11 | 1.59 | – |

| BX168 | – | 26 3/4 | – | – | – | – | 765.25 | 35.87 | 16.05 | 1.59 | – |

| BX169 | – | – | – | 5 1/8 | – | – | 173.51 | 15.85 | 12.93 | 1.59 | – |

| BX170 | – | – | – | 6 5/8 | 6 5/8 | – | 218.03 | 14.22 | 14.22 | 1.59 | – |

| BX171 | – | – | – | 8 9/16 | 8 9/16 | – | 267.44 | 14.22 | 14.22 | 1.59 | – |

| BX172 | – | – | – | 11 5/32 | 11 5/32 | – | 333.07 | 14.22 | 14.22 | 1.59 | – |

| BX303 | 30 | 30 | – | – | – | – | 852.75 | 37.95 | 16.97 | 1.59 | – |